One of the disciplines that has been most revolutionized by the advent of computer science has been that of design in all its aspects, both artistic and technical.

One of the disciplines that has been most revolutionized by the advent of computer science has been that of design in all its aspects, both artistic and technical.

Although the artistic aspect is the best known among the final public because, who more, who less, we have all used some software image retouching or drawing program, the technical side is less well known, as are its solutions, known by its acronym CAD / CAM.

CAD means Computer-Aided Design, computer-aided design in Spanish, while CAM stands for Computer-Aided Manufacturing, computer-aided manufacturing

The first discipline, CAD consists of a series of solutions of software that facilitate the design of parts or structures and even the simulation of tests of various types, such as performance or resistance.

CAD solutions are useful for engineering, industry, architecture or design

CAD computer programs not only provide the facilities to design the part or building we want, but also include elements of simulation of its physical operation, so that we can subject our designs to basic tests.

In addition, they go beyond the mere linear design of the pieces, being able to apply textures and simulate the effects of lights and shadows to end up achieving a photorealistic image, which is very useful in terms of design and communication.

One of the great advantages of CAD applications is the possibility of saving parts and elements designed to be reused within other designs, thus forming a kind of puzzle.

Therefore, if, for example, we are designing a bridge, we can focus first on an overall aspect, and then solve specific problems with parts such as clamps or cable ties, integrating them into the assembly and performing some basic simulations.

After having them finished, we can make a rendering of the whole or its parts to obtain photorealistic images.

The best known program for performing CAD tasks is AutoCAD, from Autodesk, although there are numerous solutions, including some such as software free.

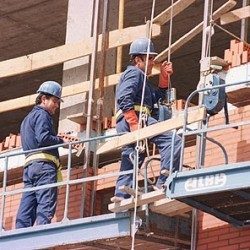

The logical continuation of the computer design process, and once it is finished, is the manufacture of the designed part or parts. And, for this, nothing better than to pass it directly from the design system to the production system, helping the process via computer thanks to computer-aided manufacturing, which involves connecting computers with the machines that manufacture the parts.

This, in turn, implies that computers must "speak" the language of the machines they produce, usually robotic arms that work side by side with human workers.

This, in turn, implies that computers must "speak" the language of the machines they produce, usually robotic arms that work side by side with human workers.

CAM offers many advantages, such as automated monitoring, quality control integrated into the production chain, and synchronization of all robots and machines involved in the manufacturing process.

The only thing we can blame CAM, as well as the introduction of any technology in production processes that people have carried out so far, is the loss of jobs, but this is not the fault of the machines, and We must be the people who fix it, since we cannot stop progress, but we can change the social model.

Photos: Fotolia - Andrei Merkulov / Xiaoliangge