Set of actions that aim to maintain an item or restore it to a proper working order

In general terms, maintenance refers to the set of actions aimed at maintaining an item or restoring it to a state in which it can perform the required function or those that it had been performing until the moment it was damaged, if there is any suffered a breakage that required the relevant maintenance and repair.

In general terms, maintenance refers to the set of actions aimed at maintaining an item or restoring it to a state in which it can perform the required function or those that it had been performing until the moment it was damaged, if there is any suffered a breakage that required the relevant maintenance and repair.

The maintenance and restoration action normally not only involves actions of a technical nature but also administrative ones.

While, At the request of the world of telecommunications and engineering, the term maintenance has several references, including: checks, measurements, replacements, adjustments and repairs that are vitally important to maintain or repair a functional unit so that it can comply its relevant functions, those actions, such as inspection, verification, classification or repair, to maintain materials in an adequate condition or the processes to achieve this condition, provision and repair actions necessary for an element to continue fulfilling the purpose for which is intended or was created and the recurring and necessary routines to keep the facilities (industrial plants, buildings, real estate) in good condition and functioning.

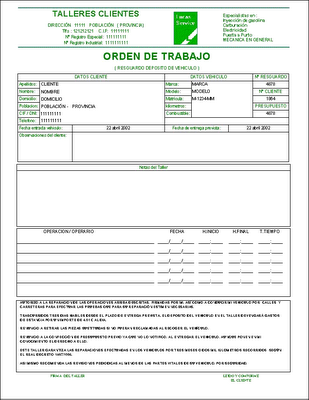

Software that allows you to manage and store all the information related to maintenance

As a consequence of the large number of elements and products that must be maintained within a company or institution, a software product has been designed that allows managing and storing all information related to maintenance. This situation occurs more than anything in industries such as aerospace, military installations, large industrial complexes or shipping companies.

This software is of great help for engineers and technicians who work in the maintenance area of any of these industries because it helps them reduce time and costs, as well as being essential to improve service and communication between those legs involved in the process. In addition, through this program you can manage projects, plan them, carry out maintenance histories, record the number of series of parts and materials, among other issues.

Types of maintenance

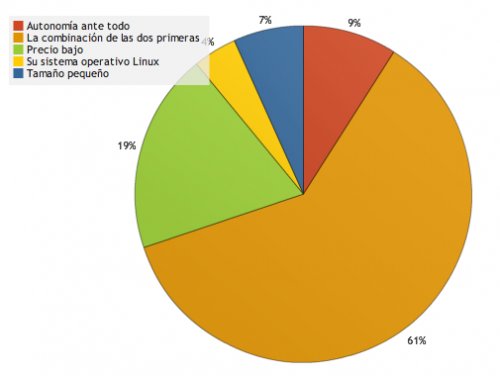

Now, we can find two types of maintenance, upkeep maintenance and preventive maintenance.

In the case of conservation, it will have the mission of compensating for the damage that occurs to equipment as a result of its use or the action of any other agent that may affect deterioration. What this type of maintenance will do is act precisely on the damaged element, correcting it or replacing it with a new one so that the device in question can continue to be used. Meanwhile, this maintenance can be carried out as soon as the problem is detected or at the time it has been identified.

And for its part, preventive maintenance is characterized by being one that anticipates any problem that may arise on equipment and machinery. So, in this sense it is that it carries out controls, relays, to follow the operation and thus anticipate a damage or breakage.

The maintenance area in charge of compensating for breakages

In many companies that work with equipment and machinery, more or less sophisticated, and even in organizations or educational or health centers, it is usual that there is a maintenance area that will precisely be in charge of the control and surveillance of all the equipment that is used. used in it. And when a damage occurs in one that could not be prevented, your mission will be to act immediately to recover that damaged equipment or device.

In many of these places that we mention, the equipment or machines usually have a great relevance in the daily work and for case if one suffers any damage, this will negatively impact the correct operation and activity of the organization or company.

The maintenance area must always be attentive to everything and must have the necessary technical resources to be able to intervene satisfactorily every time they are needed.